Xiamen, Fujian Nov 17, 2025 (Issuewire.com) - For a global client, the value of choosing an ISO 9001 certified manufacturer like Xiamen Citius Filter Media Technology For a global client, the value of choosing an ISO 9001 certified manufacturer like Xiamen Citius Filter Media Technology Incorporated Company extends far beyond a static productit is a guarantee of reliability and a partner in problem-solving. Incorporated Company extends far beyond a static productit is a guarantee of reliability and a partner in problem-solving.

A brands authority in the industrial world is built on a foundation of trust and consistent quality. This principle is at the core of Xiamen Citius Filter Media Technology Incorporated Company, a company that has established itself as a premier China Nano-Micron Powder Filter Press Manufacturer. Unlike others, the firm validates its technological prowess with a proven track record of excellence, fortified by its ISO 9001 certification. This comprehensive quality framework governs every aspect of the companys operations, ensuring its advanced technical fabrics consistently meet the global standards and solidify its position as a trusted industry leader.

ISO 9001 and the Perfect Fusion of Technology

At Xiamen Citius Filter Media Technology Incorporated Company, quality is not an afterthought; it's a philosophy embedded in the company's DNA. The ISO 9001 certification serves as a testament to its robust quality management system, providing a meticulously controlled environment for the research, development, and manufacturing of its filtration products. This systemic approach is what allows the firm to deliver consistent performance and exceptional reliability, providing a level of assurance that is critical for industries with zero tolerance for failure. This meticulous attention to detail is why the company has become a trusted China Best Dewatering Equipment Exporter, providing high-performance components that are foundational to the efficiency of industrial operations.

From Fiber to Fabric: Rigorous Quality Control

The quality journey begins long before a product is woven. It starts with the meticulous selection and inspection of raw materials. The companys procurement team sources only the highest-grade polymer fibers, subjecting each batch to a battery of tests for purity and molecular integrity. This strict control over raw materials ensures that every thread woven into a filter cloth possesses the inherent strength and durability required for high-performance applications.

During the manufacturing process, the companys state-of-the-art weaving looms are monitored by a sophisticated quality assurance system. Technicians perform continuous, real-time checks on key parameters such as tension, weaving density, and pore size uniformity. Any deviation from the precise specifications triggers an immediate alert, allowing for instant corrective action. This proactive approach prevents defects from accumulating and ensures the integrity of the finished fabric.

Finally, every roll of filter cloth undergoes a comprehensive series of final inspections. The quality control lab conducts rigorous tests on tensile strength, air permeability, and micron retention to verify that the product meets or exceeds both internal standards and industry benchmarks. It is this multi-layered approach to quality controlfrom the raw fiber to the finished fabricthat makes the firm a trusted partner for clients worldwide.

More On Newsinterestcorp ::

- La Donna Keesee, Recognized by BestAgents.us as a 2025 Top Agent

- DTFPrinter.com Launches to Revolutionize the Custom Transfer Printing Experience for Crafters and Creators

- inYantra Technologies Recognised Among the Top EMS Companies in India

- Eric Halem Calls for Safer, Smarter Driving Culture Among Enthusiasts

- Global Trusted OEM 5G Router Manufacturer with CE/EN18031/FCC/RoHS Certification and ISO 9001 Quality Control

Engineering Excellence and Quantifiable Standards

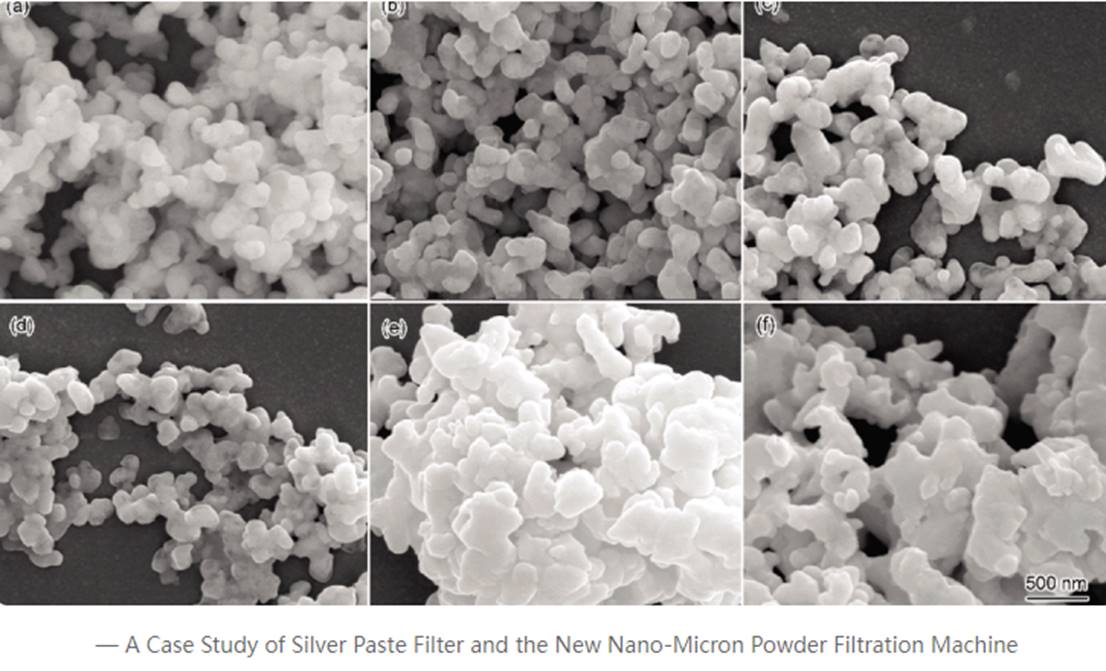

At the company, quality is an intrinsic part of its technological innovation. The company's unique mono-multifilament hybrid weaving technology and the New Nano-Micron Powder Filter Machine are perfect examples of this fusion. This proprietary method could not be executed without a flawless quality management system. The ISO 9001 framework ensures that the complex weaving parameterssuch as warp and weft tension, density, and weave patternare precisely controlled. This quality oversight guarantees that every filter cloth produced exhibits the same high-level performance. Similarly, the meticulous calendering process, which gives the fabrics their smooth surface for easy cake release, is subject to strict ISO standards for temperature and pressure control. This ensures that the final product not only performs as designed but does so with unwavering consistency in every batch.

The firms quality management system is fundamentally driven by data. Through continuous monitoring and testing protocols, the company has a proven history of producing products with an exceptionally low rate of manufacturing defects. The performance of its filter fabrics is consistently demonstrated through internal tests, which are then validated against strict quality benchmarks. For instance, the companys technology guarantees a filtration precision of 25nm and a retention rate of up to 99.9%quantifiable standards that are a direct result of its rigorous ISO-certified processes.

Real-World Value: The Return on Trust

For a global client, the value of choosing an ISO 9001 certified manufacturer like Xiamen Citius Filter Media Technology Incorporated Company extends far beyond a static productit is a guarantee of reliability and a partner in problem-solving. The technical team approaches each project with a deep understanding that no two filtration challenges are identical. The team collaborates closely with clients to analyze their specific process parameters, including slurry composition, temperature, pH levels, and required throughput. This consultative approach, guided by its stringent quality protocols, ensures that the proposed solution is precisely engineered for the client's unique operational environment.

Beyond the Product: Expertise in Diverse Applications

The firm's expertise allows it to provide tailored solutions across a wide range of industries, each with its own specific demands.

Mining and Metallurgy: In this sector, where abrasive particles and high pressure are common, the firm engineers filter cloths with enhanced tensile strength and abrasion resistance, ensuring extended service life and reduced maintenance costs. Specific applications include tailings dewatering and the processing of other abrasive mineral slurries.

Chemical and Pharmaceutical: For these sensitive industries, where product purity is paramount, the company provides specialized filter fabrics with precise micron ratings and chemical resistance to prevent contamination and ensure consistent end-product quality. Key applications involve the filtration of materials such as calcium carbonate, fertilizer, aluminum oxide, and titanium dioxide.

Environmental Protection: In dewatering sludge or waste materials, efficiency is key. The fabrics are designed for optimal cake dewatering and superior cake release, significantly reducing the energy consumption required for subsequent drying processes and improving overall operational efficiency. This includes the efficient dewatering of municipal sludge and various industrial waste liquids.

New Energy: As a leading provider of innovative filtration solutions, the company has pioneered the development of materials for the rapidly growing new energy sector. Its products are vital for the efficient and pure processing of lithium battery anode and cathode materials, ensuring the high standards required for energy storage technology.

Food and Beverage: Here, hygiene is the top priority. The firm manufactures food-grade filter cloths that meet strict sanitation standards, ensuring the final product is safe for consumpion while maintaining high filtration clarity. Key processes include starch and sugar processing.

This commitment to understanding and solving specific industry pain points is what defines the company's value proposition. It is a promise of performance, consistency, and a strategic partnership built on the unwavering foundation of quality.

Conclusion: Why Quality is Paramount

In an increasingly competitive market, the decision to choose a supplier goes beyond just price and product features. It is a strategic choice rooted in trust and reliability. Xiamen Citius Filter Media Technology Incorporated Companys commitment to quality, as validated by its ISO 9001 certification, is a powerful differentiator. It assures customers that every product, from the core fibers to the final calendering process, is held to the highest possible standard. This relentless pursuit of excellence is what empowers the firm to build long-lasting partnerships with clients across the globe. By choosing the company, customers are not just buying a filter cloth; they are investing in a promise of performance, consistency, and a partnership built on the unwavering foundation of quality.

Contact us: [email protected]

Media Contact

Xiamen Citius Filter Media Technology Incorporated Company

86-13950107241

No. 16-22 Chunfeng East Road, Xiang'an Torch High tech Zone, Xiamen City, Fujian Province, China

Source :Xiamen Citius Filter Media Technology Incorporated Company

This article was originally published by IssueWire. Read the original article here.