Yongzhou, Hunan Jan 19, 2026 (Issuewire.com) - As global manufacturing embraces electrification, miniaturization, high-frequency electronics, and energy efficiency, ceramic substrates have emerged as one of the most mission-critical building blocks of the future. From semiconductor modules and sensors to fuel-cell assemblies and wide-bandgap power electronics, material purity and dimensional accuracy dictate real-world reliability. At the forefront of this strategic shift, alumina ceramic substrate manufacturer China Mingrui Ceramic has become a key technological enabler, supporting industries that depend on high-performance ceramics for thermal, dielectric, and mechanical stability.

Chinas advanced ceramics landscape has rapidly transformed over the past decadefrom simple forming and sintering operations into globally competitive precision machining, composite formulation, and substrate integration capabilities. This evolution has been accelerated by emerging industrial requirements. Electronic devices are becoming thinner while processing more heat; EVs and photovoltaic systems require more durable insulation layers; laboratories and research platforms need stable ceramic carriers for measurement, sensing and microstructural studies. Mingrui Ceramic, backed by mature green machining and tight-tolerance processing expertise, is helping shape this new development direction.

Precision and Purity as Competitive Influence

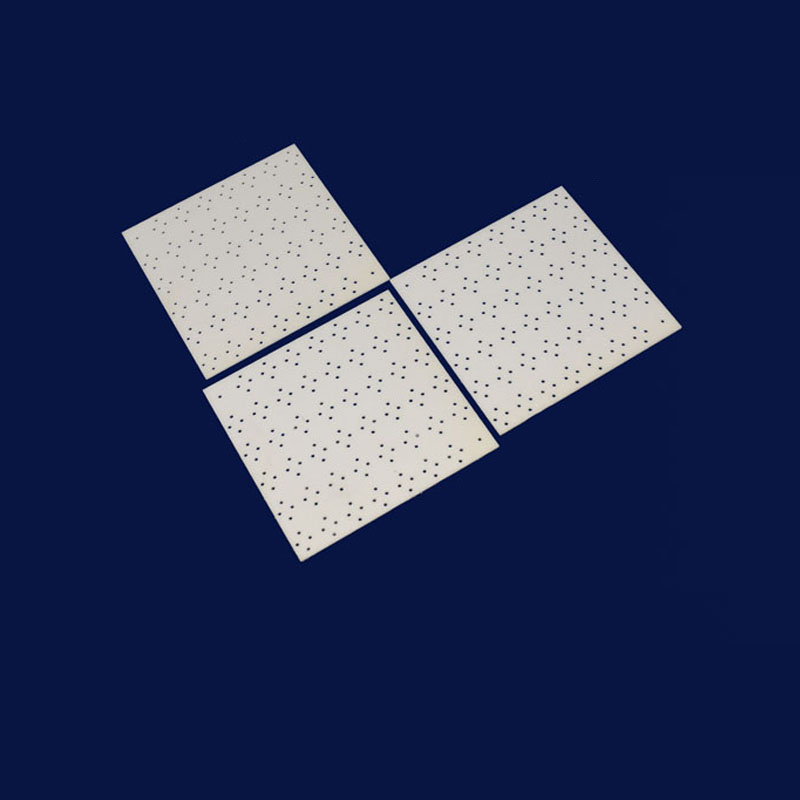

Mingrui Ceramic offers full-cycle support for substrate manufacturingfrom green machining to dimensional refinement and polishingbased on customer designs or digital models. The companys capabilities allow finishing accuracy to be matched to the geometry, thickness, and structural complexity of the substrate. This flexibility is critical for applications where planar pressure control, chip-mounting accuracy, and electrical performance depend on uniform flatness.

The companys high-purity alumina substrates benefit from optimized material handling, shrinkage control during sintering, and strict tolerance strategies refined over years of production. These steps allow substrates to maintain thermal stability, resist corrosion, and provide insulation even in high-current or harsh environments.

Chinas Growing Innovation Footprint in Advanced Ceramics

Chinas role in ceramic substrate innovation continues to expand as its manufacturing ecosystem shifts from cost-focused models to capability-driven competition. Mingrui Ceramic exemplifies these developments through accumulated process expertise, inspection maturity, and engineering engagement models.

Its investment in advanced machineryincluding Coordinate Measuring Machines (CMMs) operated by highly trained inspection staffallows substrates and other ceramic components to be validated to tight specifications. The company has proven to customers that improvement in machining strategy is equally important as material formulation, and both factors have elevated Chinas position in the global ceramic supply chain.

More On Newsinterestcorp ::

- MAFE and GEN Cameroon Sign Historic Partnership Agreement at Global Entrepreneurship Congress 2025

- China Metal Fabrication Supplier: Why Openex is Your Best Choice

- Erica Strandberg, DO: A Holistic Approach to Family Medicine in Lander, Wyoming

- Jennifer White, Recognized by BestAgents.us as a 2025 Top Agent

- Ethereum's Surge Drives Breakout Potential for Three Altcoins, Making DL Mining the Optimal Choice

Engineering-Driven Manufacturing: The Real Advantage Behind Industrial Ceramic Growth

While many suppliers provide substrates in basic formats, Mingrui Ceramic differentiates itself through collaborative engineering. For customers from semiconductors, research, energy, medical instrumentation, or fluid control systems, the company evaluates surfaces, thickness uniformity, chamfer configuration, and planarity requirements. This allows substrate geometry to be optimized before machining, reducing failure risks and enhancing compatibility.

For designs requiring high-thermal cycling endurance or extreme corrosion resistance, Mingrui Ceramic offers material recommendations and surface refinement strategies. This service modelbridging precision manufacturing with application insightrepresents the evolution of Chinas ceramic industry beyond product supply toward value-driven engineering collaboration.

Trust Indicators: Reputation, Validation, and Industry Recognition

One defining signal in Chinas ceramic transformation is its adoption of internationally recognized production standards. Mingrui Ceramic is an ISO-certified precision ceramic machining specialist. Its industry maturity is reflected in how it deploys process controls, inspection logic, documentation systems, and continuous improvement frameworks.

Its customer portfolio includes premier universities, corporate research centers, and technology enterprisesgroups known for rigorous supplier evaluation. By supporting these organizations with substrate and component solutions, Mingrui Ceramic has built credibility across aerospace development, microelectronics research, battery innovation environments, and test platform construction.

Why Substrates Matter More Than Ever

Alumina ceramic substrates sit at the center of new industrial landscapes because they:

- dissipate heat from power modules

- provide stable mounting bases for high-density circuitry

- function as insulation barriers for power conversion

- resist chemical exposure in electrochemical systems

- support precision motion structures

The increasing complexity of these systems means substrate tolerance, purity and microstructural control determine downstream performance reliability. As such, industry demand is shifting toward suppliers with experience in machining precision, multi-application usage, and process validationcapabilities Mingrui Ceramic has strengthened through high-mix production and OEM project collaboration.

Supporting High-Growth Sectors

Mingrui Ceramic has expanded its substrate development support for markets including:

- wide-bandgap power semiconductors (SiC/GaN)

- advanced control modules and electric drives

- laboratory sensor platforms and miniaturized testing instrumentation

- precision optics assemblies

- robotics and automation systems

- fuel cells and new-energy devices

Customers benefit from substrate flatness consistency, defect-free surfaces, and dimensional reliability that reduce mounting stress and improve heat dissipation efficiency.

The Cultural Shift Behind Chinas Ceramic Industry

Chinas advanced ceramic industry is progressing not only through equipment but through accumulated knowledge. Mingrui Ceramics technicians and engineers have refined internal machining techniques, crack-suppression mechanisms, design feasibility insights, and coating adaptability through years of customer project support. This evolution is what positions leading Chinese manufacturers at the forefront of high-purity substrate development.

At the same time, Chinas investment into research, automation, and measurement technologies generates a reinforcing cycle: better technology adoption fuels ceramic capability, enabling wider industrial application, which further stimulates national innovation capability.

Chinas Outlook: Moving Beyond Utility Toward Innovation Leadership

As China positions itself deeper into semiconductor packaging, high-energy conversion, medical device precision, and smart manufacturing infrastructure, ceramic substrates will become even more strategically important. Manufacturers capable of substrate integration and micro-machining will not simply support productionthey will influence digital transformation, energy efficiency standards, and engineering competitiveness.

Mingrui Ceramic is one of the companies leading this transition by linking material science with machining discipline and application-level expertise. Its performance in precision substrate development reflects where Chinas advanced ceramic sector is heading: quality-driven, innovation-focused, glbally competitive.

Conclusion

Chinas ceramic substrate industry has shifted into high-precision, application-driven territory, and Mingrui Ceramic represents this momentum through refined machining, substrate engineering leadership, high-purity processing, and customer-driven project services. For sectors requiring substrate accuracy that aligns with next-generation electronics, energy, and scientific instruments, Mingrui Ceramic continues to advance what Chinas ceramic manufacturing capability can deliver.

For more details, please visit: https://www.mrceramicpart.com/

Source :Yongzhou Mingrui Ceramic Technology Co., Ltd

This article was originally published by IssueWire. Read the original article here.